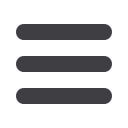

This is Rob (left) and Andy (right)

working on the nose and hood fit.

To say the finished car is good is a

gross understatement. The term “flaw-

less” is overused, especially since

being human and flawless are contra-

dictory. That said, what these guys did

was absolutely incredible. The lines

and panel fit of 3179 really do appear

to be flawless. In the years since the

car was finished, Pat and I have re-

ceived countless comments with re-

gard to how perfectly straight and

well-fitting the car’s panels are. What

people can’t see is the exceptional at-

tention to detail and workmanship be-

hind the panels. Areas that will never

be seen again are as close to perfect as

possible. As I observed the progress,

the idea of watching artists bringing a

sculpture to life came to mind. It was

inspiring.

As the car was coming together we

developed friendships and discussed

what period-correct components “we”

(the new team) should keep. The Lake-

wood bellhousing and drive shaft loop

would go. I had installed the traction

bars in 1972 and being functional and

period correct, they could stay. The

Hurst Competition Plus was a gift

from Pat a year before we were mar-

ried. No question that would remain.

The most visible departures from

Shelby correctness were the black side

strips and taillight panel. When I

bought the car back in 1971, those

changes had already been made. Now,

all these years later, they were part of

the car’s “character.” It was the only

way we knew the car. We spent a lot of

time pondering what we should do. In

the end, the black remained.

About the time the car was finish-

ing up at Mid-Cities, Rob and Andy de-

cided to branch out on their own. The

plan wasn’t to do general repair work,

interiors or full restorations. They

were going to concentrate on the mar-

ket segment where they excelled:

metal work. That’s when GT’s Mus-

tang Shop was born. With a simple

business plan, an old leased garage

without heat and two hard working

guys, a solid business with exceptional

product took off.

When they were in the leased

garage I was often able to drop in dur-

ing the day to see what was in the

works and to watch as they built the

tools and fixtures that enabled them

to become more efficient. Even though

I wasn’t a part of the process, I felt

good for them; I enjoyed watching the

shop evolve and listening to their war

stories. Their first cars included a ‘69

GT350 Hertz car, several ‘69 and ‘70

R-code Cobra Jet Mach Is, over fifteen

‘69 and ‘70 Boss 302s and a ‘67 GT500

from Sweden.

Like many small business owners,

they had to work the occasional week-

end and travel. Of course, those week-

ends and travel events were often

associated with events such as the an-

nual Mid-America Ford Meet in Tulsa,

Oklahoma. While the guys were cer-

tainly hard working and dedicated to

their customers, they did understand

the need to step away on occasion. One

afternoon when I stopped by to see

what was going on, they were gone.

Turns out, they decided it would be a

good day to head to the lake. To be fair,

this is Texas and it was the middle of

summer.

About two years after starting the

business they were able to move into

their own shop, one they built specifi-

cally for doing metal work. It’s signifi-

cantly larger and more efficient, and

well suites their needs for the mo-

ment. Unfortunately, in a sense, there

are signs of pressure. With their cus-

tomer base and backlog growing,

they’re feeling constrained and look-

ing at options to add capacity and ca-

pabilities. For example, vintage racing

appears to be in demand and has a

good potential to increase business. In

a break from the restoration metal

work, Rob and Andy delivered several

Mustang unibodies and completed roll

cages for vintage racing. They antici-

pate more to follow. Still, the core in-

terest and competency is helping to

resurrect classic Mustangs and deliv-

ering near flawless metalwork. Here

are a few samples of their work.

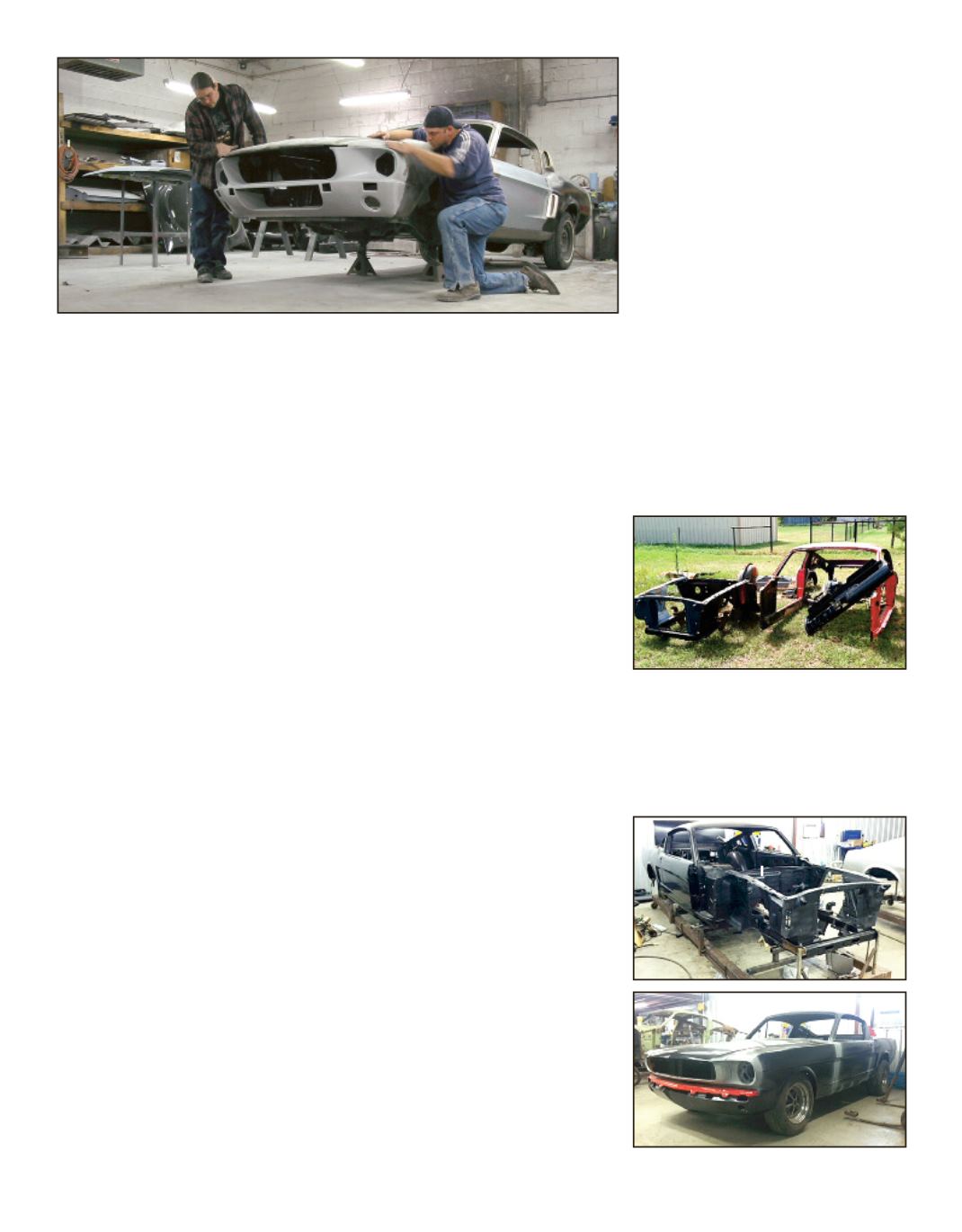

This ’66 A-code fastback came

from a customer in Indiana. The first

picture is what they started with. The

third picture is what went back to the

customer. When completed back in In-

diana, it will be powered by a Jon

Kaase Boss 429.

A longtime owner (since 1980) in

the Dallas-Fort Worth area brought

this ‘69 GT350 Shelby to them for the

The SHELBY AMERICAN

Summer 2017 69