The SHELBY AMERICAN

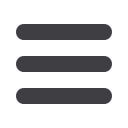

Molds come in two pieces, a top and bottom – called a cope and a drag. These are the impressions made in the sand.

This is the tooling that created the impressions seen in the photos at the top. Darker portions in the photo on the left

is sand that has yet to be removed from the mold.

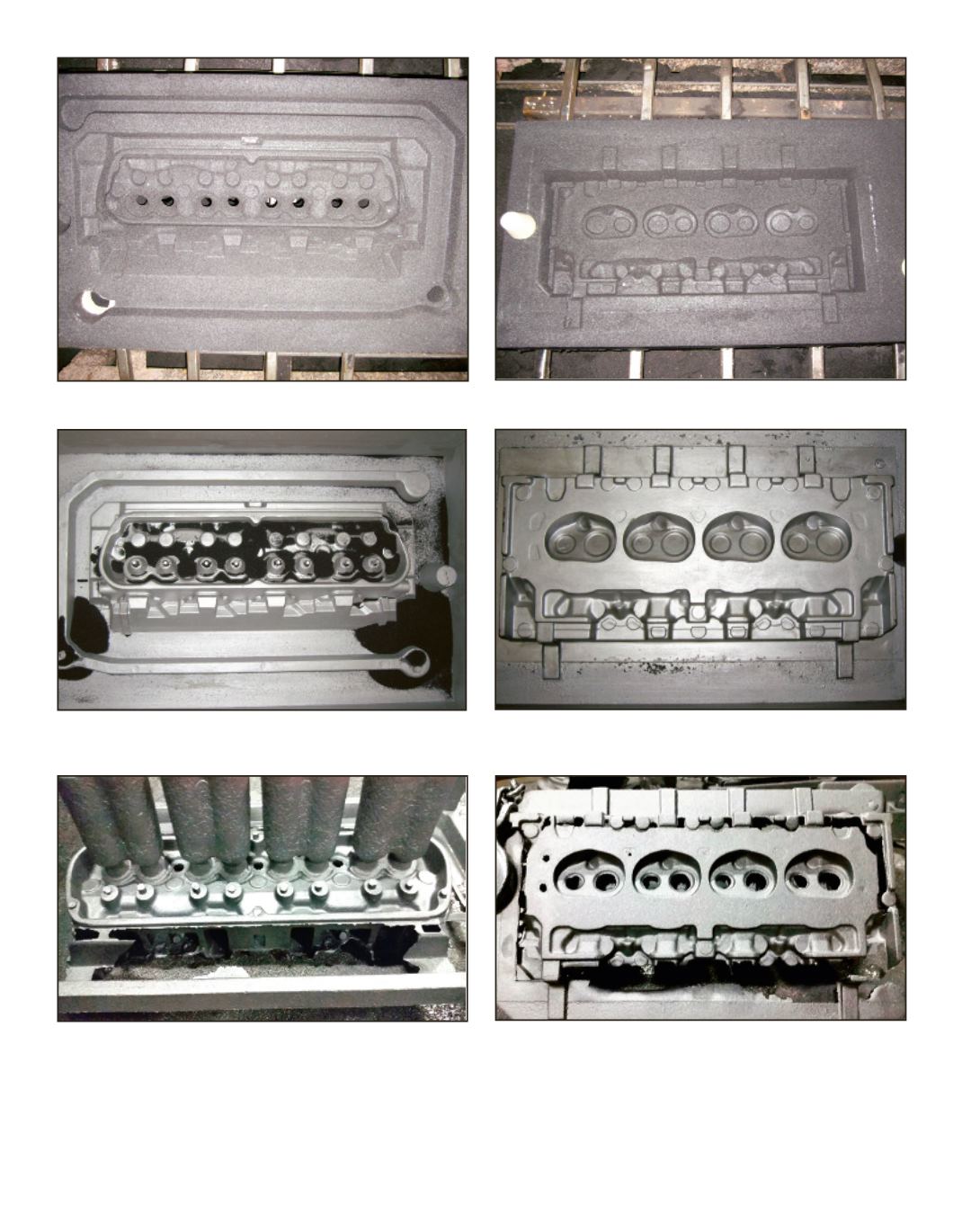

A finished raw casting. The stacks or risers are the last part of the mold filler with molten iron and they capture the

impurities, sand and air. The risers are broken off by hitting the with a hammer prior to the surfaces being ground

flush. The raw casting weighs about 125 lbs. as it comes out of the mold. After being trimmed, cleaned up and finished

it weighs 48-50 lbs. After inspection they are ready for the machine shop. Machining each head takes 2-3 hours on a

five-access, computer numerical control (CNC) machine and this process costs between $200 and $300 per head. The

cast iron material used today is stronger than what was used back in the 1960s.

Summer 2017 67