formance camshaft and induction sys-

tem. The power increase is accom-

plished through improved porting,

revised combustion chambers and in-

creased valve size. The individual

cylinder head part number is C6FE-

6049-A.”

The original tooling for these

heads was retained by Ford until

1970. At that point it was determined

that HD heads would no longer be

needed and would no longer be pro-

duced. The tooling went to Holman-

Moody, along with most of the tooling,

molds and fixtures for Ford’s other

racing engines and parts, when Henry

Ford II decreed in January of that year

that, “

We’re out of racing.

” Literally

overnight, all references to Ford’s re-

cent “Total Performance” racing his-

tory – LeMans, Indianapolis, NASCAR

and drag racing – disappeared from

Ford offices. Shelby American was

closed down and all accounts with

Carroll Shelby were settled. Holman-

Moody became the repository of al-

most all of Ford’s racing equipment,

tooling and anything else that was

deemed too important to scrap or dis-

card.

By the 1970s the 289 V8 was obso-

lete, replaced by the 302 Windsor and

Cleveland engines. The tooling for the

GT40 heads sat at Holman, amid piles

of tooling and molds for other Ford

high performance engines: 427 wedge

NASCAR and LeMans, 427 SOHC,

Boss 429, Boss 429 Can-Am, Boss 429

3-valve Calliope Can-Am, Boss 302

racing, 302 tunnelport.

Holman-Moody had already held a

couple of clearance sales and sold off

most of the “good stuff.” Due to the

lack of demand and high cost of a

short production run, no consideration

was ever given to reproducing any of

engines or heads they had tooling for,

because it would have been impossible

to even break even, much less turn a

profit. Reproducing engine blocks or

heads was very labor-intensive and re-

quired very specialized facilities.

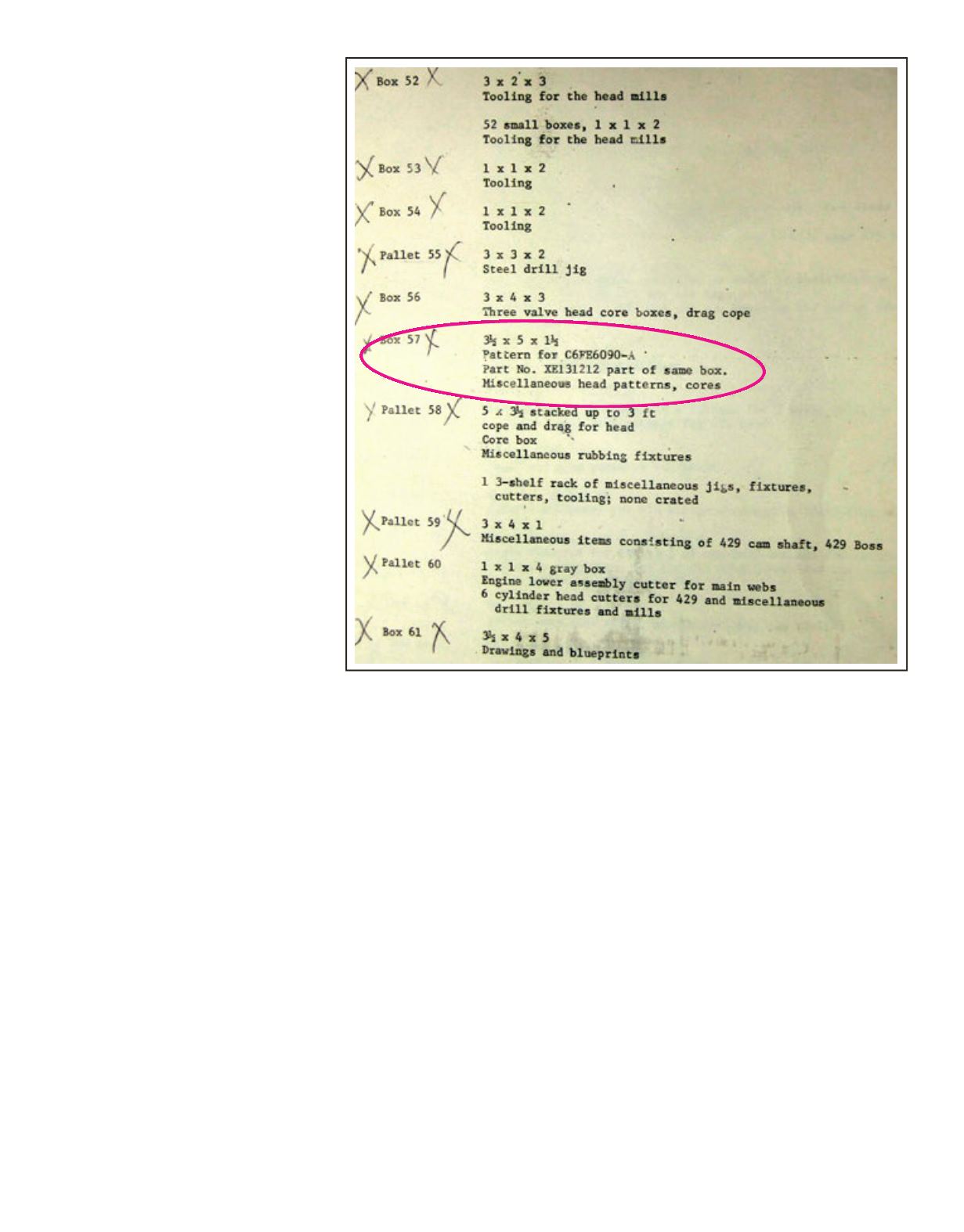

In 1981, a large inventory of tool-

ing and pieces – including the molds

for the 289 GT40 heads – was

purchased from Holman-Moody by

Alan Root/Alan Root Inc. in Ventura,

California. H-M had no plans to ever

use the tooling and it was just taking

up space. Root, a 20 year-old, was in-

terested in obtaining Boss 429 engine

patterns and tooling because, at the

time, the Boss 9 engine was the hot

NHRA pro-stock motor. H-M had no

desire to separate anything and have

it picked-over. The inventory of pat-

terns, molds and tooling took four

pages to list. Root paid between

$20,000 and $25,000 for everything.

Root invited Curt Vogt to help him

load everything up for shipment (two

tractor trailers were filled). Vogt was

curious to see what existed and was

also interested in purchasing the 427

FE engine tooling. It was, however,

later sold to Jim Dove/Dove Manufac-

turing in Columbia Station, Ohio.

Root had no qualms about sepa-

rating the tooling and selling it indi-

vidually. The C6FE GT40 head tooling

was purchased in the late 1980s by

Tony Oddo/TOE Performance in Su-

isun City, California. Oddo, a promi-

nent West Coast engine builder, saw a

demand for these heads as the B/Pro-

duction vintage racing boom escalated

in the 1980s. Racers who had to com-

ply with strict technical requirements

in order to compete at Monterey

formed enough of a pool of buyers to

make reproducing the GT40 heads

worthwhile. TOE Performance also

had special, machined billet steel, non-

roller rocker arms produced to circum-

vent Monterey’s prohibition of roller

rocker arms.

TOE Performance had 75 sets of

HD heads made in two separate

batches between the late 1980s and

2010. The first batch was machined by

Alan Root; the second batch was ma-

The SHELBY AMERICAN

Summer 2017 65

This is one of four pages of inventory for the Ford tooling, molds and fixtures. GT40

C6FE heads are circled.