could keep track of the progress.

Bryant liked it because it put some

distance between him and Rager.

However, a lot of time was lost due to

Rager’s insistence that he be made

aware of every minute detail.

As work on the aluminum chassis

progressed, Shelby began whetting ap-

petites by feeding

Autoweek

informa-

tion about the car. Their September

23, 1996 edition carried a story report-

ing that the paperwork between

Shelby and Oldsmobile had been

signed the previous week. The engine

would be the 4.0 liter, 32-valve Olds

putting out 350 horsepower. The arti-

cle went on to describe both roadster

and coupe body styles, and that the

weight would be under 2,400 pounds.

Shelby’s oft-quoted $75,000 price was

also mentioned.

With

Oldsmobile’s

original

$1,000,000 commitment gone, Rager,

Davison and Olesen were left to

search for operating capital. Rock had

suggested involving one or more well-

heeled Oldsmobile dealers but that

idea never went anywhere. The next

avenue was suppliers. A unique busi-

ness plan was put together and Rager

was able to sell it to their vendors. In

a nutshell, the vendors would pay for

developing the parts and components.

Shelby would, in return, purchase the

parts directly from them, at a price

which would cover most of the devel-

opment costs. Parts suppliers were

guaranteed that the pieces they devel-

oped would be used (instead of merely

competing against other suppliers in a

bidding process). Shelby would bear no

initial development costs (which was

perfect because they didn’t have the

money). The vendors would begin to be

paid as deposits from buyers were re-

ceived.

The company was still short of op-

erating capital.When it could, it relied

on income from CSX4000 sales. One of

the biggest obstacles turned out to be

finding a supplier for the car’s interior

pieces. The interior was a complex

area with special demands. There

were safety requirements and specific

dimensions, such as the distance be-

tween the windshield and the driver’s

head. Attention to seatbelt and

padding placement was all part of the

equation. Peter Bryant began shop-

ping for a company that could provide

interiors but he did not encounter

much success. The expense involved in

creating something from scratch was

high, and because only 500 cars would

be built, there was no promise of vol-

ume to amortize costs.

Bryant struck pay dirt when he

called on Venture Industries in De-

troit. Venture was a major auto indus-

try supplier specializing in the

manufacture of plastic moldings. They

also had experience in building proto-

types as well as interiors. After some

consideration they agreed to provide

interiors for the Series 1. They were

also interested in producing entire

bodies for the cars as a way to show-

case their experience in carbon fiber

technology. Venture had deep pockets

and Shelby would soon be plumbing

the depths.

By October of 1997 two prototypes

existed. One had appeared at the De-

troit Auto Show earlier in the year and

was now dismantled. The second car

had been turned into a rolling labora-

tory in Gardena. It showed the effects

of testing, and before being put on dis-

play for a Shelby dealers’ meeting at

the IRL race at Las Vegas Motor

Speedway, it was given new paint and

a general cosmetic once-over. Don

Rager, who had begun appearing in a

black cowboy hat, drove it around the

speedway prior to the start of the IRL

race, which was held at night. By this

time deposits had been received for

some 50 cars.

By the end of 1997 the design was

more or less finalized. The price was

set at $97,750 but dealers were told

that once production began the price

would likely go up. Everyone involved

with the project also realized that

there was no way the initial promise

of production beginning by the end of

the year could be met.

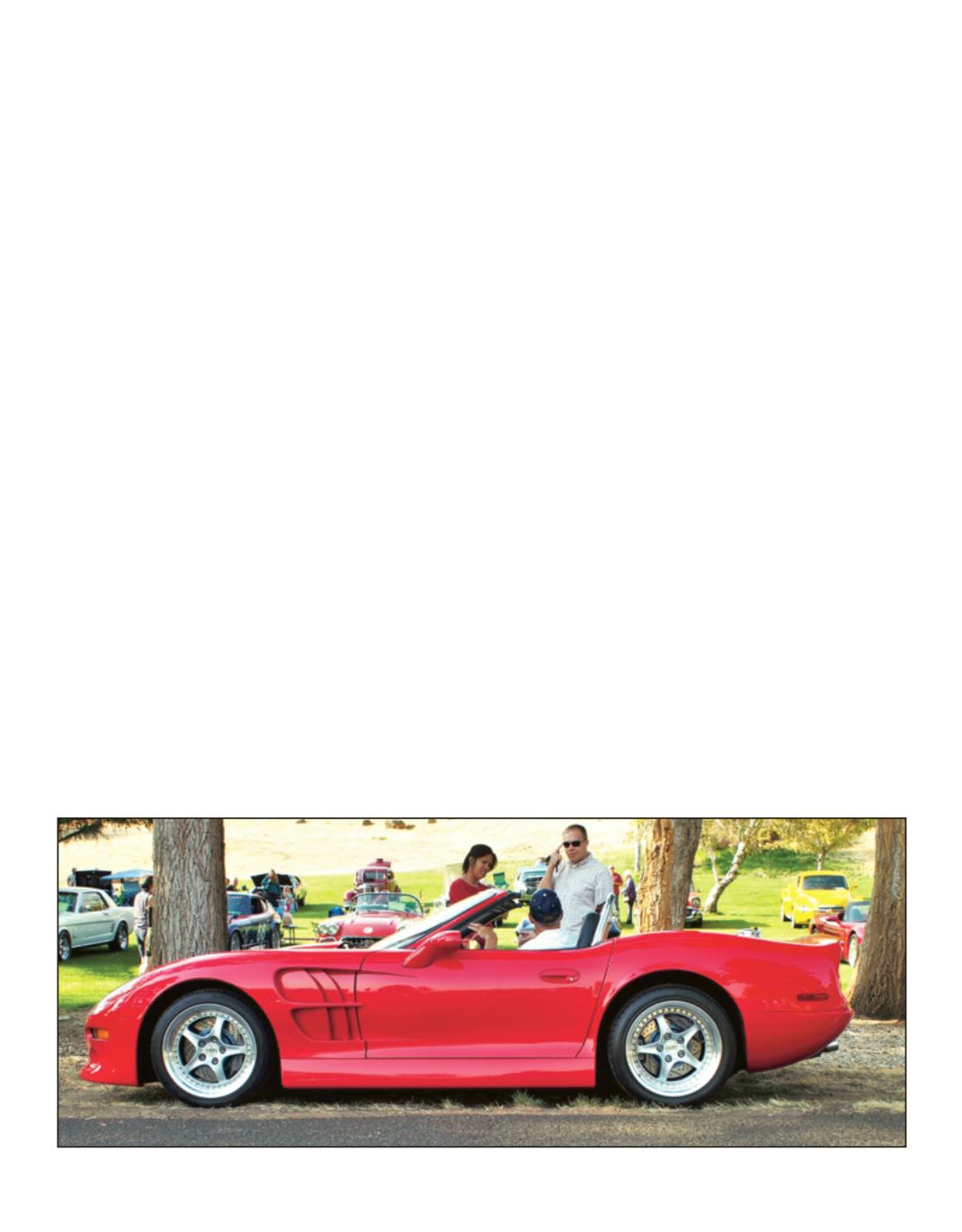

To help the dealers promote the

Shelby Series 1 prior to having any

cars to sell, a non-running mock-up

was made. It used a set of early body

panels mounted on a wooden platform.

From six feet away it was impossible

to tell it from a running car...of which

none existed because they had been

continually disassembled and re-

assembled for research and develop-

ment. The “pushmobile,” as it came to

be called at the factory, made the

rounds from dealer to dealer through-

The SHELBY AMERICAN

Fall 2016 40